Plastic products play an essential role in everyday life, ranging from household items to automotive components and packaging materials. While functionality and durability are key considerations in plastic manufacturing, the visual appeal of a product can also significantly influence consumer choice. This is where Injection Color Masterbatch and Functional Masterbatch come into play, offering solutions that enhance both the aesthetic qualities and performance of plastic products.

Understanding Injection Color Masterbatch

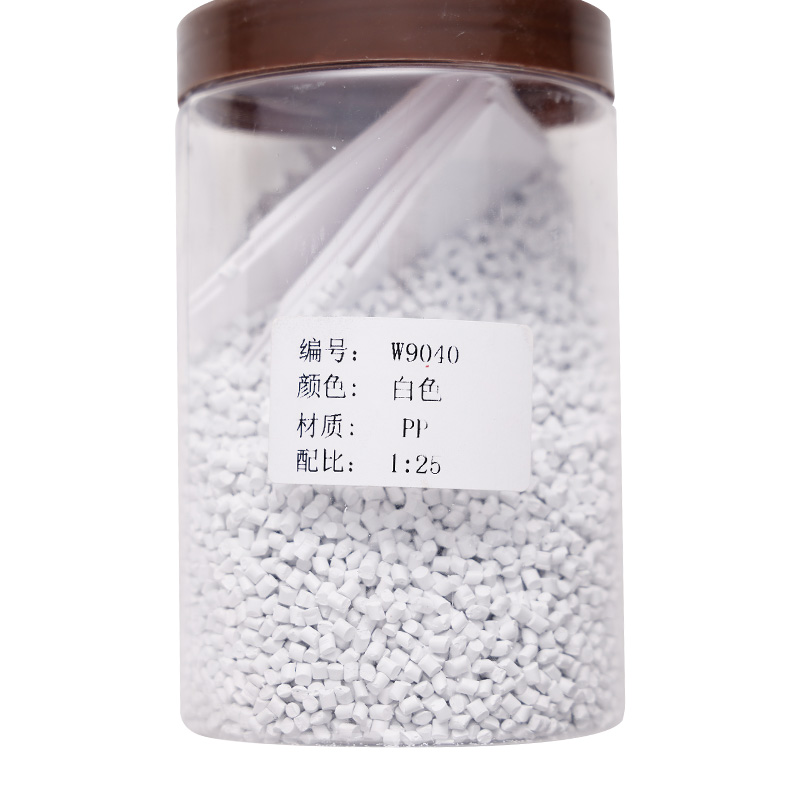

Injection Color Masterbatch is a concentrated mixture of pigments and additives encapsulated in a carrier resin. It is designed to be blended with raw plastic during the injection molding process, giving manufacturers the ability to produce vibrant, uniform, and consistent colors in their products. Unlike traditional coloring methods, using color masterbatch simplifies production and reduces the likelihood of color variation, which is particularly important for products that require a consistent appearance across multiple batches.

The flexibility of injection color masterbatch allows manufacturers to tailor the intensity of color according to specific requirements. By adjusting the proportion of masterbatch in the plastic formulation, a wide range of shades and tones can be achieved. This adaptability is particularly valuable in industries such as consumer electronics, home appliances, and automotive interiors, where precise color matching can enhance brand identity and product appeal.

Benefits Beyond Color

While the primary function of injection color masterbatch is to provide color, it can also improve the overall quality and durability of plastic products. Many color masterbatches include additives that enhance resistance to UV light, heat, or chemical exposure. For example, UV-stable masterbatches help prevent discoloration and surface degradation when products are exposed to sunlight for extended periods. Heat-resistant formulations can maintain color and structural integrity during high-temperature applications, such as automotive parts or kitchen appliances.

Another advantage of using color masterbatch is the reduction of waste. Because the masterbatch is concentrated, manufacturers need smaller quantities compared to traditional pigments or dyes. This not only lowers material costs but also less environmental impact, making it a more sustainable option for modern production practices.

Exploring Functional Masterbatch

In addition to aesthetic improvements, Functional Masterbatch plays a critical role in enhancing the performance of plastic products. Functional masterbatches incorporate additives that impart specific properties, such as flame retardancy, anti-static behavior, antimicrobial effects, or impact resistance. These masterbatches allow manufacturers to integrate additional functionalities directly into the plastic during processing, eliminating the need for secondary treatments or coatings.

For instance, antimicrobial masterbatches are widely used in medical equipment, food packaging, and household items to inhibit the growth of bacteria and fungi. Flame-retardant masterbatches improve safety in electrical components, construction materials, and public transportation interiors. Anti-static masterbatches help prevent dust attraction and static discharge in sensitive electronic devices. By combining functional additives with color masterbatches, it is possible to achieve both visual appeal and enhanced material performance in a single production step.

Applications Across Industries

Injection color and functional masterbatches are employed in a variety of sectors due to their versatility. In the automotive industry, they contribute to the production of interior trims, dashboard components, and protective housings with consistent color and resistance to environmental stressors. In consumer goods, they allow manufacturers to create visually appealing products such as toys, storage containers, and kitchenware while ensuring durability and compliance with safety standards. In packaging, color masterbatches improve brand recognition and shelf appeal, while functional masterbatches provide barrier properties, UV protection, or antimicrobial benefits.

Choosing the Right Masterbatch

Selecting the appropriate masterbatch requires careful consideration of the desired properties, processing conditions, and end-use environment of the plastic product. Factors such as resin type, molding technique, exposure to heat or UV light, and regulatory requirements should guide the choice of color and functional additives. Collaborating with suppliers to identify compatible masterbatches can streamline production, reduce defects, and improve product quality.

Injection Color Masterbatch and Functional Masterbatch are essential tools for manufacturers seeking to enhance both the appearance and performance of plastic products. By combining vibrant, consistent colors with functional additives that improve durability, resistance, and safety, these masterbatches offer a practical and efficient solution for modern plastic production. As industries continue to demand more from plastic materials, the role of masterbatches in achieving visually appealing, high-quality, and functional products will remain significant.

English

English Español

Español русский

русский