In today’s competitive manufacturing landscape, OEMs are increasingly relying on color innovation to differentiate their products. Social media trends and consumer demand for visually striking goods have fueled interest in Injection Color Masterbatch for standard vibrant colors, as well as Pearlescent Color Masterbatch for premium, shimmering finishes. Manufacturers now play a pivotal role in helping clients maintain consistency, achieve special effects, and respond quickly to design trends.

The Importance of Consistent Color Across Production Runs

For OEMs, color consistency is not just aesthetic—it directly impacts brand perception. Minor deviations in shade or finish can advance to product recalls or customer complaints. High-quality color masterbatches provide predictable dispersion, stable pigment load, and uniformity across different production batches. From a manufacturer’s perspective, investing in precise formulations and process control ensures clients can maintain quality across multiple molds, lines, and production sites.

Social Media and Market-Driven Color Choices

Platforms like Instagram, Pinterest, and TikTok have amplified the visibility of new design trends, often showcasing unique hues, metallic finishes, and pearlescent textures. These trends influence purchasing decisions, pushing OEMs to adopt both standard and specialty masterbatches that align with consumer expectations. By partnering with an experienced manufacturer, OEMs can access tailored color solutions that reflect current design aesthetics while remaining technically reliable.

Why Pearlescent Masterbatches Are Becoming a Preferred Solution

Pearlescent Color Masterbatches provide a luxurious, eye-catching appearance that standard pigments cannot achieve. Their reflective qualities, subtle shimmer, and layered visual effects add a premium feel to automotive parts, consumer electronics, and decorative packaging. OEMs seeking differentiation increasingly request pearlescent effects to enhance perceived value, brand recognition, and overall product appeal.

Key Selection Criteria for OEM Buyers

When sourcing color masterbatches, OEMs and plastic processors consider multiple factors to ensure efficiency and reliability:

- Uniform pigment dispersion for consistent color quality

- Processing stability under injection molding or extrusion conditions

- Compatibility with different polymer resins, including PP, ABS, and PET

- Customization options for proprietary color codes and visual effects

- Technical support and documentation from manufacturers

By meeting these criteria, manufacturers can strengthen long-term partnerships and reduce production risk for their clients.

Customization and Flexible Solutions for Diverse Applications

Modern OEMs often require tailored solutions to meet brand and product differentiation needs. Manufacturers offer options such as:

- Custom shades and specialty effects to match brand identity

- High-opacity or translucent formulations for unique visual presentations

- Additives for UV stability, flow improvement, or gloss enhancement

- Compatibility with both injection molding and extrusion processes

These capabilities allow OEMs to create distinctive products that stand out in crowded markets, leveraging the expertise of trusted manufacturers.

Sustainability and Material Efficiency

Sustainable production practices are increasingly important in international markets. Efficient color masterbatches reduce pigment waste and enhance processing stability, minimizing scrap and energy consumption. Manufacturers who prioritize pigment efficiency and eco-conscious formulations help clients meet corporate sustainability goals while maintaining attractive product appearances.

Manufacturing Expertise: The Foundation of Trust

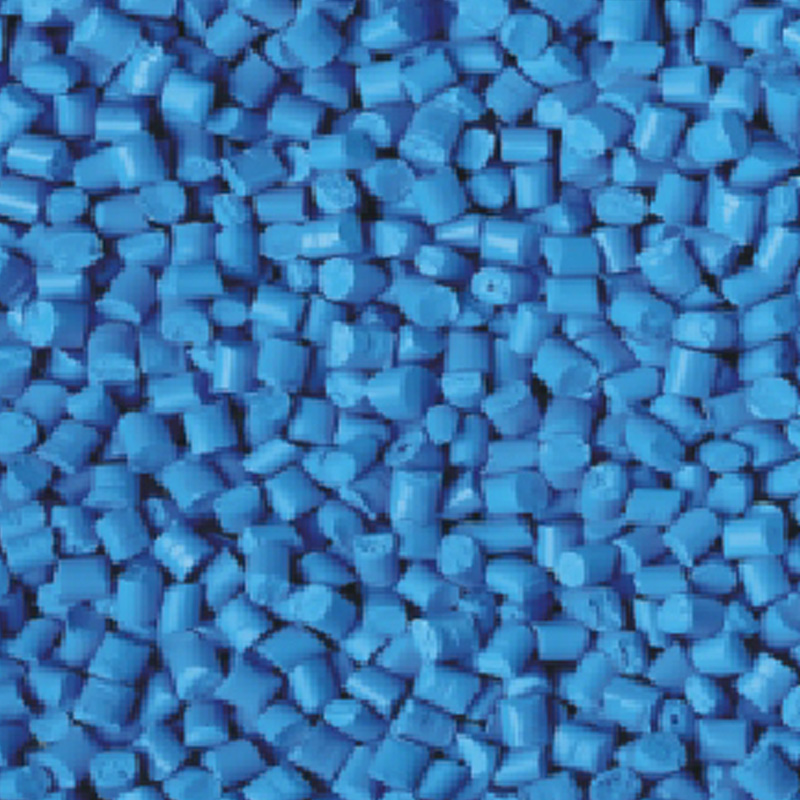

As a manufacturer, we ensure each masterbatch meets strict quality control standards, including precise pigment dispersion, stable pellet formation, and repeatable processing behavior. This reliability ensures that OEMs can confidently produce large volumes of high-quality parts without color variation or production interruptions. Long-term consistency strengthens client confidence and builds lasting partnerships.

Delivering Innovation Through Reliable Masterbatches

In a market where appearance often drives consumer choice, reliable Injection Color Masterbatch and Pearlescent Color Masterbatch are essential tools for OEMs seeking to differentiate their products. By combining manufacturing expertise, advanced pigment technology, and flexible customization options, manufacturers enable clients to achieve consistent, eye-catching finishes while meeting efficiency, sustainability, and design objectives.

English

English Español

Español русский

русский