Injection molding is a widely used manufacturing process, especially in producing plastic components with complex shapes and high precision. In this process, color masterbatch plays a crucial role in ensuring consistent coloration, improved aesthetics, and even functional properties for molded parts. Among the different types of masterbatches, injection color masterbatch and functional masterbatch stand out as essential solutions to meet the diverse needs of injection molding applications.

Injection color masterbatch is specially formulated to provide uniform and stable coloration during the injection molding process. It contains concentrated pigments or dyes dispersed in a carrier resin compatible with the base polymer. This composition allows easy blending with the raw polymer material, ensuring the final product has consistent color distribution without compromising mechanical properties. The flexibility of color masterbatch lets manufacturers adjust shades and tones according to specific project requirements, whether subtle hues or vibrant colors are needed.

One of the key advantages of using injection color masterbatch lies in its ability to maintain color stability under the high temperatures and pressures typical of injection molding. Some pigments can degrade or fade when exposed to such conditions, but the formulations used in these masterbatches are designed to resist thermal and chemical stress. This results in molded parts that retain their intended appearance through production and throughout their service life.

Beyond coloration, functional masterbatch solutions have gained attention for their ability to add performance-enhancing features to molded components. Functional masterbatches incorporate additives that provide specific properties, such as UV resistance, flame retardancy, antimicrobial effects, or improved impact strength. These features are integrated during the molding process without the need for separate treatments, streamlining production and reducing costs.

For example, UV stabilizer masterbatches can help protect outdoor plastic parts from degradation caused by prolonged sun exposure. Flame retardant masterbatches contribute to safety by reducing the flammability of materials used in electronics housings or automotive interiors. Meanwhile, antimicrobial masterbatches find applications in medical devices or food packaging by inhibiting the growth of bacteria on plastic surfaces.

Combining injection color masterbatch with functional masterbatch can yield components that not only meet aesthetic standards but also comply with technical requirements. This dual approach is particularly beneficial in industries like consumer electronics, automotive, and healthcare, where appearance and performance go hand in hand. Manufacturers can tailor their masterbatch blends to suit material specifications, regulatory standards, and end-use environments.

The selection of carrier resin in masterbatches is another important factor influencing processing and product quality. Compatibility between the masterbatch carrier and the base polymer ensures smooth melt flow, preventing defects such as streaks, spots, or poor dispersion of additives. This compatibility also impacts the mechanical properties of the final product, helping maintain strength, flexibility, and durability.

Additionally, the particle size and dispersion of pigments within injection color masterbatch affect the surface finish and color uniformity of molded parts. Fine and well-dispersed pigments advance to smoother finishes and more consistent coloration. Advances in pigment technology continue to improve the performance of masterbatches, allowing manufacturers to achieve a wide range of colors with stable properties.

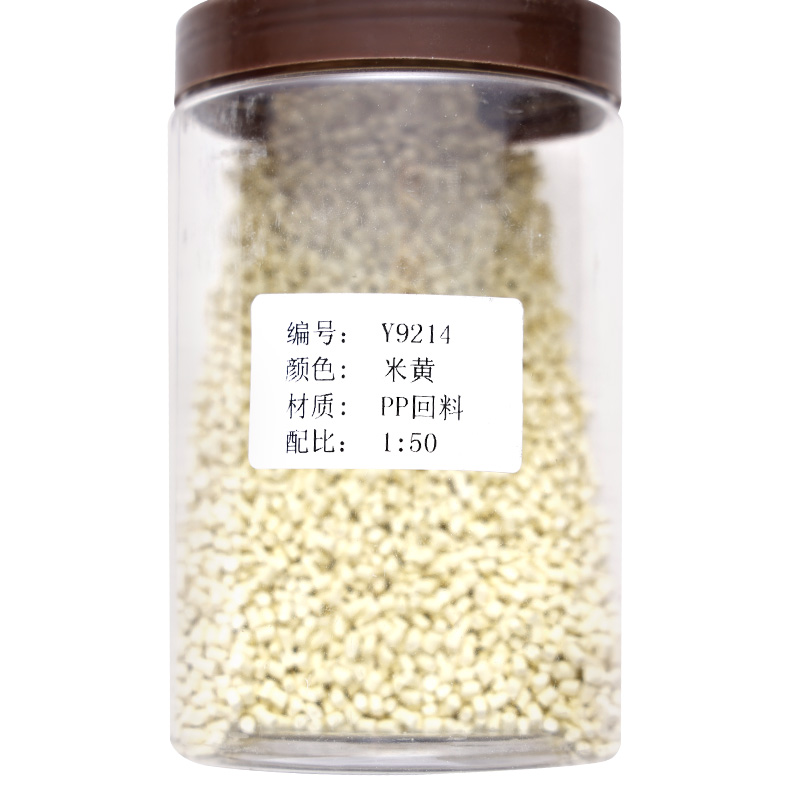

From a production standpoint, masterbatch solutions contribute to efficiency and cost-effectiveness. By providing concentrated additives in pellet form, masterbatches simplify handling and dosing compared to liquid colorants or powders. This reduces waste, enhances mixing accuracy, and reduces downtime. Furthermore, using masterbatches can reduce the amount of raw pigments needed, lowering overall material costs while maintaining quality.

Sustainability is also a consideration in the development of masterbatch products. Some formulations now incorporate recycled materials or biodegradable carriers to align with environmental goals. Functional masterbatches can enhance recyclability by enabling easier sorting or adding protective properties that extend product life, thereby reducing environmental impact.

Color masterbatch solutions offer versatile and reliable options for precise injection molding applications. Injection color masterbatch ensures consistent and stable coloration, while functional masterbatch adds value through performance enhancements. Together, they help manufacturers produce plastic components that meet both aesthetic and technical demands. Selecting the right masterbatch involves considering compatibility, pigment quality, and desired functionalities to achieve good results throughout the manufacturing process.

English

English Español

Español русский

русский