Taizhou City Chuanghui Master Batch Co., Ltd.

Factory

News

-

Industry News 2024-04-16

In the realm of master batches production, additive masterbatches play a crucial...

-

Industry News 2024-04-16

The plastic industry has long been a driving force in modern manufacturing, prov...

-

Industry News 2024-04-16

Pearl pigments and pearlescent pigments are prized for their ability to impart a...

-

Industry News 2024-04-16

To ensure the desired properties and performance of these products, it is essent...

Plastic Master Batch Industry Knowledge Extension

The modern world is continuously evolving, and with it, the demand for innovative materials and advanced technologies. Plastic master batch, thermoplastic materials, and color materials polymer are three essential components that have significantly impacted various industries. These materials have become indispensable in the manufacturing process, offering a wide range of applications and advantages.

Plastic master batch is a concentrated mixture of additives and carriers, designed to provide specific properties to the final plastic product. These master batches are used in various applications, such as packaging, automotive, construction, and consumer goods. The primary advantage of using plastic master batch is its ability to enhance the performance of the base polymer, providing improved strength, durability, and resistance to environmental factors. Additionally, plastic master batch can be easily incorporated into the manufacturing process, ensuring consistent distribution of the additives throughout the final product.

Thermoplastic materials are a class of polymers that can be melted and reshaped multiple times without significant degradation of their properties. This unique characteristic makes them highly versatile and suitable for a wide range of applications. Some common thermoplastic materials include polyethylene, polypropylene, and polyvinyl chloride (PVC). The primary advantage of thermoplastic materials is their ease of processing, as they can be easily molded, extruded, or injection-molded into various shapes and sizes. Furthermore, thermoplastic materials are highly customizable, allowing manufacturers to tailor their properties to meet specific requirements.

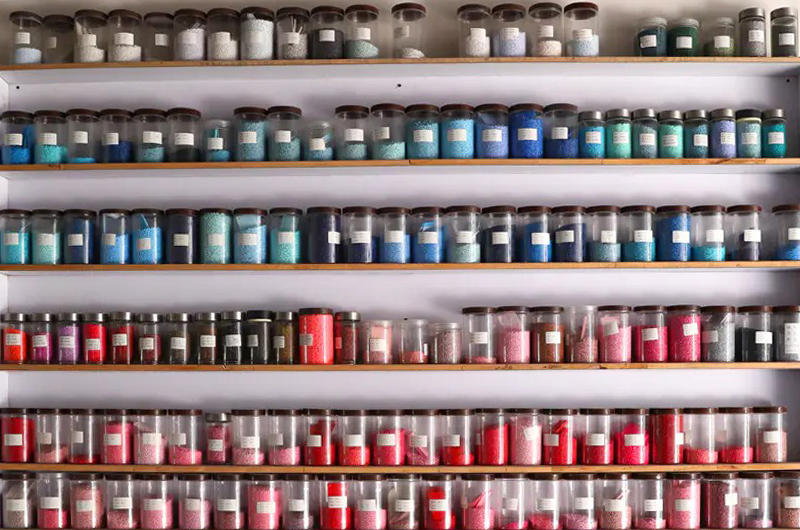

Color materials polymer, on the other hand, are polymers that have been specifically formulated to provide a desired color and appearance to the final product. These color materials polymers are widely used in various industries, such as automotive, electronics, and consumer goods, where aesthetics play a crucial role in the product's success. The primary advantage of using color materials polymer is the ability to create a consistent and visually appealing final product. This consistency is achieved by incorporating the color directly into the polymer, ensuring that the color remains uniform throughout the material.

The combination of plastic master batch, thermoplastic materials, and color materials polymer has revolutionized the manufacturing industry, providing manufacturers with a versatile and efficient solution for producing high-quality products. One notable application of these materials is in the automotive industry, where they are used to create lightweight, durable, and visually appealing components. By incorporating plastic master batch into thermoplastic materials, manufacturers can enhance the strength and durability of the components, while color materials polymer ensures a consistent and attractive appearance.

Another significant application of these materials is in the packaging industry. Plastic master batch and color materials polymer are widely used to create innovative and sustainable packaging solutions. By utilizing thermoplastic materials, manufacturers can easily mold and shape the packaging to meet specific requirements, while plastic master batch and color materials polymer ensure the desired properties and appearance are achieved. This has led to the development of eco-friendly packaging solutions, such as biodegradable and reusable containers, which have a reduced environmental impact.

The construction industry has also benefited from the use of plastic master batch, thermoplastic materials, and color materials polymer. These materials are used in the production of various construction components, such as pipes, insulation, and cladding. The incorporation of plastic master batch into thermoplastic materials enhances the durability and resistance of these components, while color materials polymer provides a consistent and visually appealing appearance. This has led to the development of more sustainable and energy-efficient construction solutions, contributing to the growth of green building practices.

In the consumer goods market, plastic master batch, thermoplastic materials, and color materials polymer have become essential components in the production of various products, such as toys, appliances, and electronics. The versatility and customizability of these materials allow manufacturers to create innovative and visually appealing products that cater to the diverse needs and preferences of consumers.

English

English Español

Español русский

русский