In the ever-evolving landscape of the polymer industry, the use of black masterbatches has emerged as a critical factor in enhancing both the performance and aesthetics of plastic goods. From automotive components to consumer electronics, black masterbatches play a pivotal role in achieving the desired properties and appearance of polymer-based products.

Understanding Black Masterbatches:

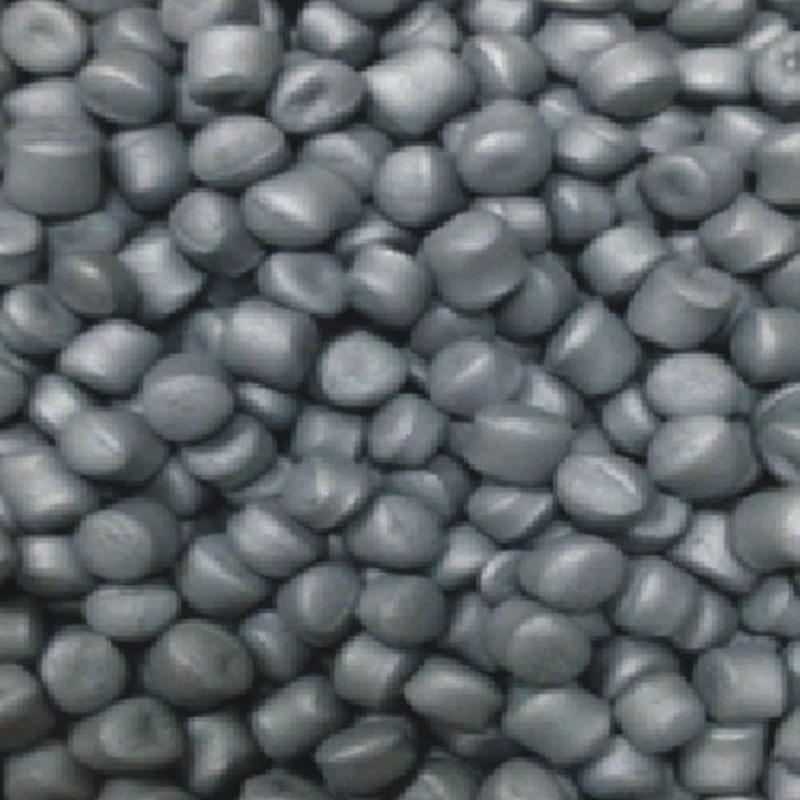

Black masterbatches are concentrated formulations of carbon black, a finely divided form of carbon, dispersed in a polymer carrier resin. These masterbatches serve as additives that impart various desirable properties to plastic products, including coloration, UV resistance, conductivity, and enhanced mechanical strength. The versatility of black masterbatches makes them indispensable in a wide range of applications across industries.

Key Applications in the Polymer Industry:

In the polymer industry, black masterbatches find widespread use in the manufacturing of plastic goods across diverse sectors. In the automotive industry, black masterbatches are employed in the production of exterior trim components, interior panels, and under-the-hood parts. The deep black coloration provided by these masterbatches enhances the visual appeal of automotive parts while offering UV resistance to withstand prolonged exposure to sunlight.

Optimizing Performance and Durability:

One of the primary functions of black masterbatches is to improve the mechanical properties and durability of plastic goods. By incorporating carbon black into polymer matrices, manufacturers can reinforce the structure of plastic products, increasing their tensile strength, impact resistance, and dimensional stability. This is particularly crucial in applications where durability and reliability are paramount, such as in construction materials, industrial components, and outdoor furniture.

Achieving Uniform Coloration and Consistency:

Another essential aspect of black masterbatches is their role in providing consistent coloration and surface finish to plastic goods. The uniform dispersion of carbon black particles within the polymer matrix ensures that the desired black color is evenly distributed throughout the product, eliminating streaks, blotches, or inconsistencies. This uniformity is vital for achieving high-quality finished products that meet stringent aesthetic standards in industries such as consumer electronics, packaging, and household appliances.

Addressing Environmental Challenges:

In addition to enhancing performance and aesthetics, black masterbatches can also help address environmental challenges in the polymer industry. By incorporating recycled carbon black derived from post-consumer waste or industrial by-products, manufacturers can reduce their reliance on virgin carbon black and promote sustainable practices. This not only minimizes the environmental impact of plastic production but also contributes to the circular economy by closing the loop on material usage.

Innovation Driving Market Growth:

The market for black masterbatches continues to expand as manufacturers invest in research and development to innovate new formulations and applications. Advanced technologies, such as nano-sized carbon black particles and functional additives, are enabling the development of masterbatches with enhanced properties, such as anti-static, flame-retardant, and anti-fogging capabilities. These innovations open up opportunities for black masterbatches to penetrate new markets and cater to evolving customer demands.

Collaborative Partnerships for Success:

The success of black masterbatches in the polymer industry relies on collaborative partnerships between raw material suppliers, masterbatch manufacturers, and end-users. Close collaboration allows for the customization of masterbatch formulations to meet specific performance requirements and aesthetic preferences. By working together throughout the supply chain, stakeholders can ensure the successful integration of black masterbatches into plastic goods that meet the highest standards of quality and performance.

Black masterbatches play a vital role in enhancing the performance, durability, and aesthetics of plastic goods across various industries within the polymer sector. Through their ability to provide uniform coloration, improve mechanical properties, and address environmental challenges, black masterbatches have become indispensable additives in the production of high-quality plastic products.

English

English Español

Español русский

русский